Manufacturing Process of Test Hose Fittings

With over 10 years experience&ISO 9001 system&SGS management, Ikin offer 15-30% lower cost test hose fittings with high performance.

Home » hydraulic test point hose&end fitting » hydraulic test hose

Top 3 Manufacturer in China–IKIN fluid

Microbore high-pressure test hose&assembly usually have nominal diameter of 2/4/6mm.

It is used to test pressure in the hydraulic system, and used in conjunction with the pressure test point.

With designed structure, it has advantages of light weight,easy use. and reliable sealing.

Connections are divided into 24°male cone, 37°JIC, flat surface, bulkhead and others, and customized accepted.

Working temperature range:-40℃~120℃

Product characteristics: oil resistance, acid and alkali resistance, high pressure resistance.

Ikin test point hose is a new generation product, with many characteristics that traditional hoses cannot match.

Suitable for hydraulic, pneumatic, high-pressure spraying, high-pressure cleaning, liquid sandblasting, resistance to various greases, gases, acid and alkali resistance, etc. Aging resistance is 3 times stronger than that of rubber pipes.

Pressure measuring system of all kinds of equipment, such as construction machinery, machine tools, ships, railways, mining, petrochemicals, automobiles, agricultural machinery, electricity, compressors, air conditioning and refrigeration equipment, aviation, medical equipment, hydraulic systems, pressure measuring equipment, etc.

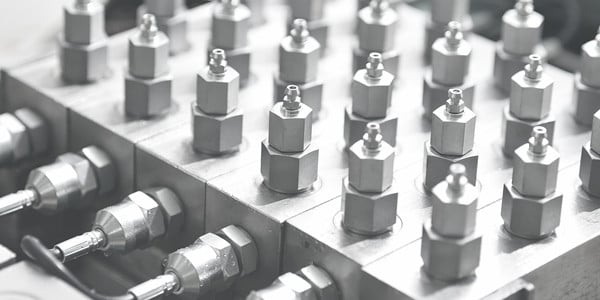

Pictures are taken in kinds of exhibitions. Ikin test couplings are widely used in hydraulic valves& system of heavy industry, agriculture, mining, marine industry etc.

With over 10 years experience&ISO 9001 system&SGS management, Ikin offer 15-30% lower cost test hose fittings with high performance.

The round bar material is cold-drawn formed from world-class drawing equipment.

Over 100pcs high precision machining, ensure the size accuracy and mass production delivery.

The necessary inspection of semi-finished guarantee the fittings quality.

Fully automatic assembly line make sure the efficiency and accuracy.

Leakage for hydraulic test fittings is a big trouble for hydraulic system. Ikin insist 100% leakage test before finished. And 3 years guarantee.

Ordinarily 100pcs/bag, 2 bags/carton. Seal with tape and then pack with shrink film machine. Make sure the cartons clean and safe.

Fully automated assembly equipment, make our hydraulic fittings 15%-30% lower cost with same quality.

Over 10 years experience and specizlized technic team, make us be supplier for Sany Crane, Eaton, Hawee Hydraulic, Bucher and so on.

Fast delivery will be 10 working days. Over 100pcs high precision machine, 5 workshops, 8 production line, make us top 3 manufacturer in China.

Ikin is supplier for Hawe Hydraulic, Sany Crane, Eaton and so on. We aim at larger market inbroad and ourbroad. Credibility is difinitely most important for us.

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected

*We respect your confidentiality and all information are protected

*We respect your confidentiality and all information are protected