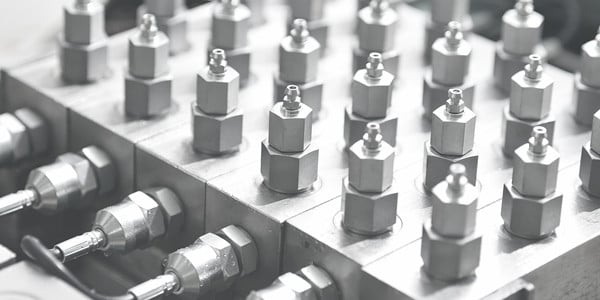

Manufacturing Process

With over 10 years experience&ISO 9001 system&SGS management, Ikin offer 15-30% lower cost fittings with high performance.

Pictures are taken by mobile phone in real occasion.

With over 10 years experience&ISO 9001 system&SGS management, Ikin offer 15-30% lower cost fittings with high performance.

The round bar material is cold-drawn formed from world-class drawing equipment.

Over 100pcs high precision machining, ensure the size accuracy and mass production delivery.

The necessary inspection of semi-finished guarantee the fittings quality.

Fully automatic assembly line make sure the efficiency and accuracy.

Leakage for hydraulic test fittings is a big trouble for hydraulic system. Ikin insist 100% leakage test before finished. And 3 years guarantee.

Ordinarily 100pcs/bag, 2 bags/carton. Seal with tape and then pack with shrink film machine. Make sure the cartons clean and safe.

Fully automated assembly equipment, make our hydraulic fittings 15%-30% lower cost with same quality.

Over 10 years experience and specizlized technic team, make us be supplier for Sany Crane, Eaton, Hawee Hydraulic, Bucher and so on.

Fast delivery will be 10 working days. Over 100pcs high precision machine, 5 workshops, 8 production line, make us top 3 manufacturer in China.

Ikin is supplier for Hawe Hydraulic, Sany Crane, Eaton and so on. We aim at larger market inbroad and ourbroad. Credibility is difinitely most important for us.

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected

*We respect your confidentiality and all information are protected

*We respect your confidentiality and all information are protected.

*We respect your confidentiality and all information are protected