hydraulic test Point

Top 3 Hydraulic Test Point Manufacturer in China

SGS Approved

- Home

- Hydraulic Test Point

Hydraulic Test Coupling Products

hydraulic test point supplier introduction

- also called pressure test point, coupling for test hoses, used for pressure testing in hydraulic system.

- We are manufacturer founded in 2009, over 10 years experience.

- ISO9001 certified manufacturer, we offer wide specifications.

- All models match hydraulic system in different countries.

- Stauff/Minimess/Spradow test point fittings replacement, EMA3/1620/1215/test 20/SMK 20 series could be exchanged here.

- You will get the excellent quality goods with lower cost.

Specification We Offer

- Minimess fittings replacement

- Minimess kobling replacement

- Minimess test point replacement

- Minimess coupling replacement

- Minimess 1620 replacement

- Minimess 1215 replacement

- Stauff test replacement

- Stauff smk20 replacement

- Stauff test 20 replacement

- Parker ema3 1/4ED replacement

- Parker test point fittings replacement

- Parker minimess fittings replacement

- Minimess connector replacement

- Spradow test coupling replacement

Hydraulic Test Point Selection Guide

Find the right IKIN test point for your application. Select your requirements below to see recommended products.

Mobile Equipment (Excavators, Loaders, Tractors)

Recommended for construction equipment, agricultural machinery, and mobile hydraulics. Compact design with high vibration resistance.

Industrial Machinery (Presses, Injection Molding, Machine Tools)

Recommended for factory equipment with BSPP/BSPT threads. Standard in European and Asian manufacturing.

Test Bench & Laboratory Applications

Recommended for pressure testing, R&D, and quality control. High accuracy and repeated connection cycles.

Marine & Offshore Applications

Recommended for shipboard systems and offshore platforms. Corrosion resistant materials available.

Up to 400 Bar (5,800 PSI) Products

Up to 500 Bar (7,250 PSI) Products

Up to 630 Bar (9,137 PSI) Products - Full Range

Need Help Choosing the Right Test Point?

Our technical team can help you select the perfect product for your application

Contact Technical SupportHydraulic Test Tools

Engineering calculators and reference guides for hydraulic test point selection

Thread Specification CalculatorMetric, BSPP, BSPT, NPT, UNF, JIC thread data with matching IKIN products Open Tool → |

Pressure Unit ConverterConvert Bar, PSI, MPa, kPa instantly with our reference chart Open Tool → |

Cross-Reference GuideFind IKIN replacements for Minimess, Stauff, Parker and more Open Tool → |

Test Point Application Cases

Pictures are taken by mobile phone in real occasion.

Case 1-XCMG Crane

Case 2 - Sany Crane

Case 3 - hydraulic check valve

Case 4 - hydraulic valve system

Case 5 - hydraulic pressure system

Case 6 - hydraulic valve

Cooperation Partner

Excellent Raw Material

The round bar material is cold-drawn formed from world-class drawing equipment.

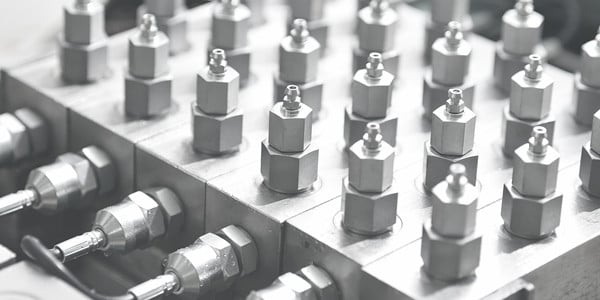

Precision Machining

Over 100pcs high precision machining, ensure the size accuracy and mass production delivery.

Semi-finished Inspection

The necessary inspection of semi-finished guarantee the fittings quality.

Automatic assembly

Fully automatic assembly line make sure the efficiency and accuracy.

Finished 100% Inspection

Leakage for hydraulic test fittings is a big trouble for hydraulic system. Ikin insist 100% leakage test before finished. And 3 years guarantee.

Sturdy Packaging

Ordinarily 100pcs/bag, 2 bags/carton. Seal with tape and then pack with shrink film machine. Make sure the cartons clean and safe.

What Guarantees The Quality Of Our test point

over 100pcs high precision machine

technic workers with over 5 years experience

ISO and SGS system management

cone design structure, no leakage for oil

Fully automated assembly equipment

100% leakage test before finished

WHY choose us

Competitive Price

Fully automated assembly equipment, make our hydraulic fittings 15%-30% lower cost with same quality.

consistent Quality

Over 10 years experience and specizlized technic team, make us be supplier for Sany Crane, Eaton, Hawee Hydraulic, Bucher and so on.

short lead time

Fast delivery will be 10 working days. Over 100pcs high precision machine, 5 workshops, 8 production line, make us top 3 manufacturer in China.

Your reliable supplier

Ikin is supplier for Hawe Hydraulic, Sany Crane, Eaton and so on. We aim at larger market inbroad and ourbroad. Credibility is difinitely most important for us.

Test Point Supplier at Fairs

Frequently Asked Questions

Common questions about hydraulic test point fittings and pressure testing

What is a hydraulic test point fitting and how does it attach to a port? +

A hydraulic test point fitting is a component that creates an access point to a hydraulic port. This allows specialists to connect measuring devices to assess the system pressure or test hose. There are male and female test point fittings. They can contain different thread types (NPT, BSPP, JIC, SAE, and metric) and materials (corrosion resistant stainless steel). They also can have a built in check valve to minimize fluid leakage and contamination when pressure testing. These fittings screw directly into port of the hydraulic system.

How do test couplings and adapters aid in the process of pressure testing? +

Adapters and test couplings provide an efficient way to connect and disconnect test hoses to hydraulic test points. Selection of an appropriate adapter (ORFS swivel, JIC, or metric) aids in ensuring proper alignment with the fitting and pressure gauge. A test coupling provides a secure, non-leaking connection to the system that allows for the addition of pressure measurement devices, and the use of pressure diagnostic tools.

Why do test point fittings need to be stainless steel for my hydraulic systems? +

When test point fittings are used in stainless steel, it is because of the highly demanding environments that they are in, which offer the ability for extreme corrosion resistance, durability, and overall cleanliness. This is for environments where an oil and its cleanliness, along with an extensive service life and exposure to extreme conditions, and with stainless steel, it aids in the retaining of reliable readings of pressures and retaining the equipment of the hydraulic system.

What are the common thread types and how do they affect connector selection? +

Common thread types for these are NPT, BSPP, JIC, SAE, ORFS, and metric threads. With these different types of threads come different sealing methods, which affect how they connect and how easy they are to install. An example of this is ORFS which is a flat-face swiveling connector that helps with sealing which aids in minimizing overall contamination. NPT is a connector that uses threading and sealant. It is very important to match the test point with the appropriate thread that is attached to the port to avoid leaks and to allow for safe testing of the pressure.

What is the correct way to measure system pressure using a test point and gauge? +

To measure system pressure correctly, use a test point fitting and a pressure gauge, both of which are pressure rated for the system (PSI or bar). Secure the test hose to a test coupling or a test adapter, and check for and remove air from the line, then slowly pressurize the system while monitoring for any leaks. To avoid contamination and damage to the equipment, use the recommended PPE and the manufacturer's instructions regarding the maximum system pressure and safe operating procedures.

What test point fittings for hose and bulkhead installations are offered? +

The types offered are inline test point fittings for hose connections, bulkhead test point fittings for panel or tank installations, and compact direct mount fittings for manifold ports. The bulkhead versions offer a sealed pass-through for mounting on bulkheads, and the hose-ends offer test hose connection for easy quick coupling. Based on access and space, as well as the need for a swivel, female, or male connection, choose the appropriate type.

How can I avoid contamination when using hydraulic test points? +

To avoid contamination, employ the use of clean test hoses, dust caps, and sealed test point fittings when not in use. Use ORFS swivel or flat-face connectors that capture dust for unvented cavities. Follow correct flushing and purging protocols before attaching gauges, and maintain the device and select the correct device components. These will all come together to reduce the risk of moisture and particulates entering a hydraulic system during pressure testing.

Is it possible to keep an eye on system pressure with a test point connector? +

Certainly, most test point connectors can allow for continuous monitoring by use of an appropriate adaptor and test coupling to attach a pressure transducer or electronic monitor. Check that the connector and the sensor are suitable for continuous monitoring, compatible threads are utilised, and that the system is kept clean during installation. Professional grade hydraulic fittings and supportive accessories will ensure effective pressure monitoring for long periods of time.

What components need to be considered when a technician chooses a test point accessory or fitting? +

Factors a technician needs to consider are system pressure rating, thread type (metric, NPT, BSPP, ORFS), material (stainless steel vs. carbon steel), connector type (male, female, swivel), accessibility, and whether a bulkhead or direct mount is necessary. In addition, assess contamination control, gauge and test hose compatibility, and whether safe, rapid measurements require an accessory such as quick test 20 or a specialized adapter. Selecting a test point fitting properly ensures safe measuring and accurate pressure readings.

Benefits You Can Find In Ikin

factory Price and low moq

reliable quality, supplier for Eaton, Hawe and so on

100% leakage Inspection Before finished

3 years warranty

10 working days for bulk shipping

match other fittings like minimess, stauff and so on

cone seal design structure, stable and long life

Get Your Free Sample

in 2 days

*We respect your confidentiality and all information are protected.