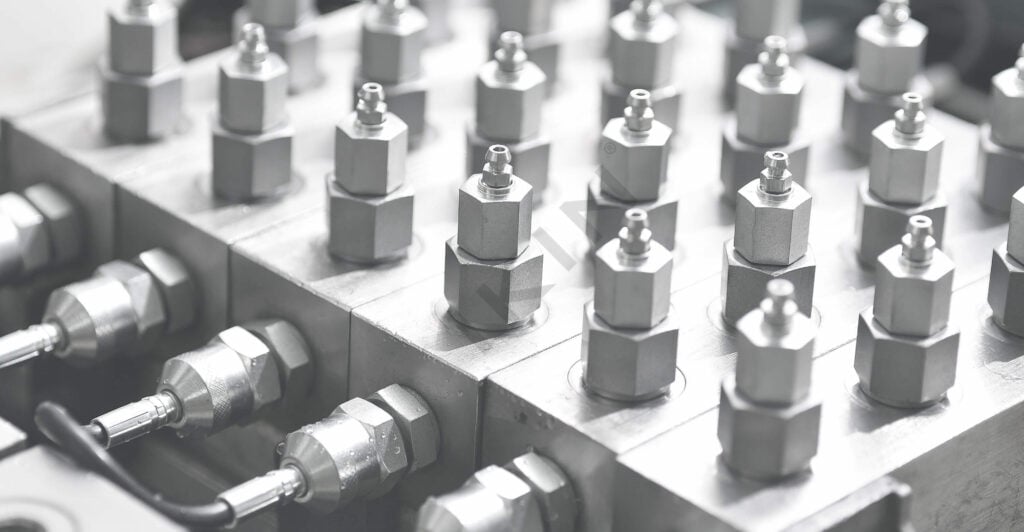

How to Avoid Middlemen and Find Quality Pressure Test Fitting / Pressure Test Hose Manufacturers in China

How to Avoid Middlemen and Find Quality Pressure Test Fitting / Pressure Test Hose Manufacturers in China In today’s fast-paced industrial environment, finding the right supplier for hydraulic pressure test