What is the function of test point in hydraulic system?

In order to simplify machinery structure design, the driving systems of modern machines commonly are driven by full hydraulic systems.

The features of full hydraulic system include reasonable overall layout, simple structure design, convenient system operation, reliable quality, strong driving power and convenient maintenance and commission.

It becomes more and more popular among users.

we manufacture hydraulic test point&hose

In order to understand the working situations of full hydraulic system comprehensively, the pressure testing points are set in the design of full hydraulic system, and pressure taps are equipped as well in the pressure testing points to measure whether the pressure in the oil way is within normal range or not, so as that the pressure can be measured quickly for troubleshooting.

I. The working principle and application of pressure test point

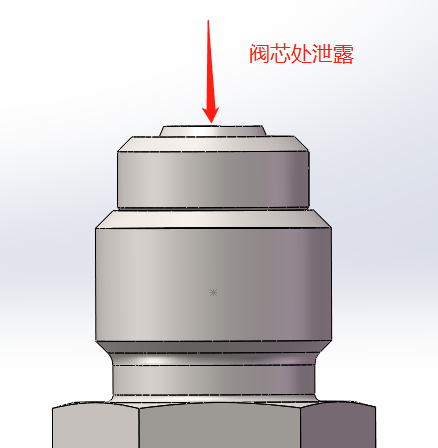

1. There is a self-sealing valve in the pressure test point. Due to the function of spring, it would be closed when used separately.

And it would be opened when it is connected with the measuring hose tube or pressure test point with same thimble to take samples and system pressure testing in the high-pressure or low-pressure fluid system.

The working pressure can reach 63Mpa, and pressure of BP can reach 250Mpa.

the video shows how Ikin hydraulic test point works

2. The pressure test point is mainly used in the full hydraulic tubing system for pressure supervision detection, gas discharging, samples taking in the high-pressure and low-pressure systems.

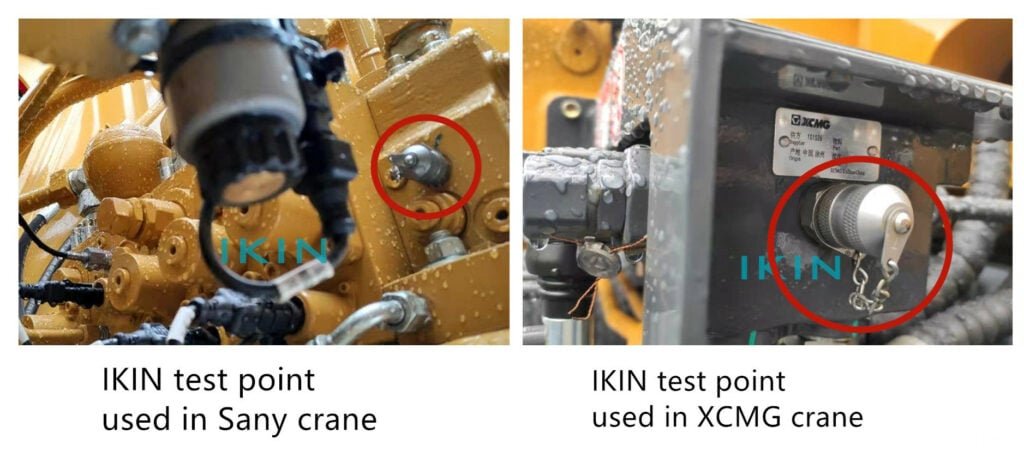

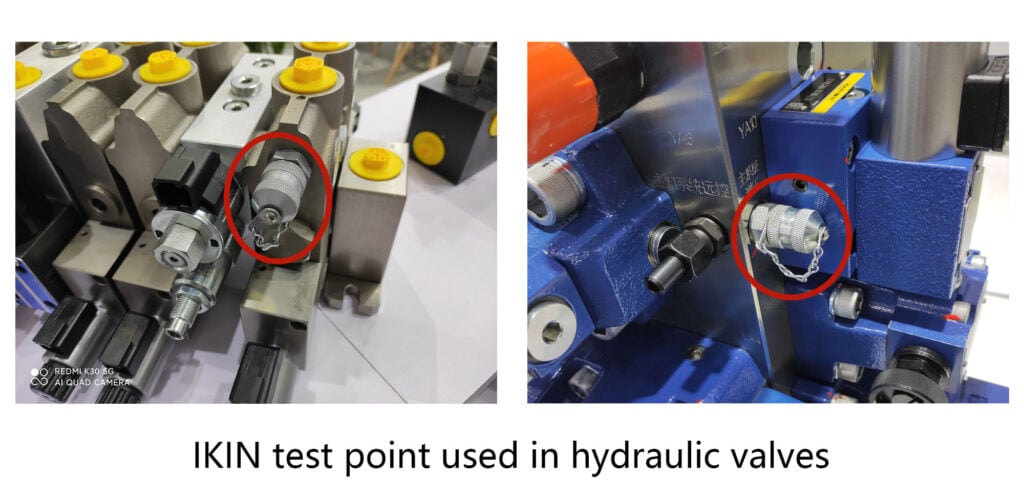

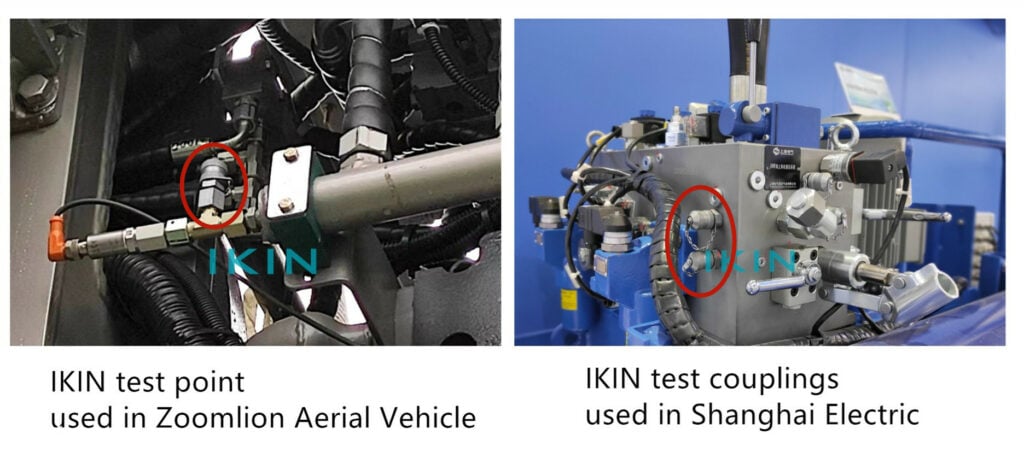

It is widely used in the engineering machinery, agricultural machinery, hydraulic system, testing equipment and so on.

For example, the hydraulic system and operating of hydraulic excavator are complicated, but how to judge hydraulic failures?

Shown as the below picture, pressure test point is needed now to measure the hydraulic pressure of testing point so as to find the root of the problem.

The pressure tap can bear pressure testing in the hydraulic system, which is critical significant for stable hydraulic equipment and reliable operation.

Therefore, pressure test point is widely used as standard configuration in current hydraulic systems.

II. The necessity of setting Hydraulic testings

The whole moving system driven by hydraulic system is integrated by hydraulic motor, hydraulic action component, hydraulic valve, oil pipes and others. It is very complicated.

The pipe line from oil pump to hydraulic action components is long, as well as the hydraulic flowing distance. It is hard to predict press loss as fluid flowing direction and flowing speed changes.

It is difficult for system commission and inconvenient for maintenance.

As a result, the features of full hydraulic system should be taken into full consideration in the design. Pressure testing points should be set and hydraulic testing should be equipped.

Meanwhile, the cost of hydraulic testing is low, installation location is flexible, and it is not limited by working environment with long usage life.

It is benefit for hydraulic system commission and working performance of hydraulic system could be improved.

III. Convenient for failures diagnosis in full hydraulic system

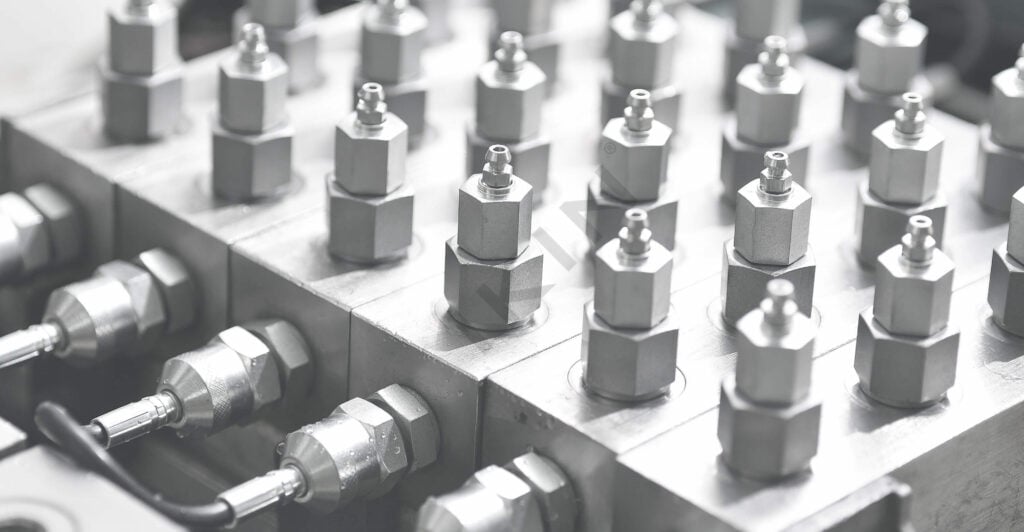

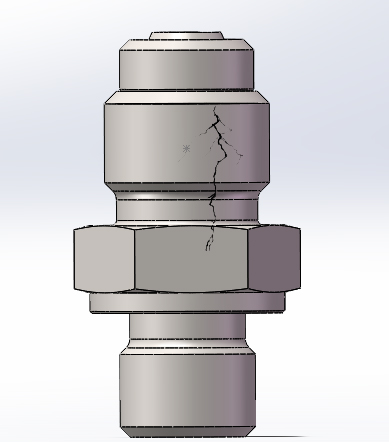

The full hydraulic system is complicated, and number of hydraulic motors and integrated valve blocks are many, leading the probability of failures is high. Once failures happen, finding the reasons of failures quickly is the key in troubleshooting.

Installing hydraulic testing in full hydraulic system can analyze the reasons that may happen through pressure testing in all pressure points.

With the help of hydraulic testing to analyze potential reasons for failures in full hydraulic system, it is very good at troubleshooting and finding out reasons for failures.

IV. Improve the working performance of full hydraulic system

The number of pumps and motors in full hydraulic system is many, and flow capacity of oil is high. Due to the limitation of machinery structure, the flowing distance of hydraulic oil in the oil box is short, bubble exudation rate is low, and huge amounts of bubbles would be brought into pipeline again.

Hydraulic test point installed in hydraulic pipeline can be used to release gas in higher parts that are gathered in the hydraulic pipeline so as to make compensation for the shortage of low bubble exudation, which is very beneficial for decreasing hydraulic impacts and improving working performance of system.

V. Conclusion

The number of hydraulic components and action parts is many in the full hydraulic system, and system is complicated.

Machinery structure, working environment, special demands and various issues that may happen should be taken into full account when design full hydraulic system equipment.

It is very necessary to adopt various methods comprehensively to improve working performance and maintainability.

Generally speaking, in the improving the reliability of quality, the advantages of proper adapting hydraulic testing in full hydraulic system equipment are more than disadvantages, which are also very beneficial for commission and performance improvement in full hydraulic system.

What we supply?

—— Top 3 manufacturer in China

Benefits You Can Find In Ikin

factory Price and low moq

reliable quality, supplier for Eaton, Hawee and so on

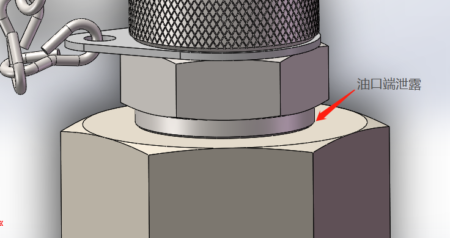

100% leakage Inspection Before finished

3 years warranty

10 working days for bulk shipping

match other fittings like minimess, stauff and so on

cone seal design structure, stable and long life

Get Your Free Sample

in 2 days

*We respect your confidentiality and all information are protected.